Jefa Rudder Bearing Maintenance

Don't forget to maintain your rudder bearings. If you have concerns take care of it now. Preventive maintenance of your Rudder Bearings is always a bargain when compared to unplanned repairs or an emergency resulting from neglect. All repairs and maintenance must be done by qualified professionals

Make a note of how the steering feels when your boat or your rudder bearings are new, or when you have just launched. Use this information for comparison if you have any work done on the steering or rudder bearings in the future.

Shortly before you haul your boat for any service, assess if there is any change in the steering or bearings and share this information with the boat yard. Inspect the steering and bearings annually and at each haul out.

Things To Check

Here are some of the common things to check if you hear or feel something unusual and believe it may be the rudder bearings.

Marine growth can be fouling the bearings.

This is most common in the lower bearing. This will have to be cleaned out. You may need to remove the rudder for this. Flushing the bearing when possible and at least annually can help avoid this.

Antifoulling paint near, on, or inside the bearing.

The wrong paint on an aluminum housing will damage it. If this happens you must replace the corroded parts. Keep copper-based paint at least 2" away from any aluminum bearing parts. The aluminum bearing housing must be prepared, primed and painted with products intended for aluminum below the water load.

High loads in one direction for a long period of time.

If you are on the same tack for days at a time you will displace the grease to the unloaded side of the bearing. The bearing will squeak until it is loaded in the other direction.

The rudder may be touching the hull.

All boats bend and twist when they are sailing. When this happens the bearing never get closer, the bearing can move further apart. If the bearings move apart the rudder may be rubbing against the hull. Have the boat yard lower the rudder slightly in relation to the upper bearing and check if the noise, vibration or squeak is gone.

A Note About Grease -

Only lubricate your rudder bearing if and where the manufacturer recommends. The rollers in a Jefa Rudder Bearing should never be greased. Self-aligning Jefa Bearings do require synthetic grease between the self-aligning sphere and the bearing housings. O-rings should also be lightly greased.

Rudder Shaft

The rudder shaft should be inspected once a year for signs of electrolysis. Circular patterns of corrosion on the shaft surface are a good sign of this. When the rudder blade has a tight fit to the hull, look at the gap. Normally it's not necessary to drop the rudder for further inspection, unless the rudder system has developed backlash or if the shaft rotates irregularly. If you have any concern for electrolysis, please read Jefa's electrolysis page carefully.

Important tips and guidelines on how to use antifouling on the rudder blade and rudder shaft can be found in Jefa's antifouling instruction document.

Another area for attention on the rudder shaft is the locking of the tiller arm or quadrant on the shaft. Carefully inspect to see if there's movement between the parts. Any movement could wear out the keyway in the shaft which can lead to costly repairs.

Bottom Bearing

The bottom bearing doesn't usually need any maintenance except for rinsing with water when the ship is hauled out. The main reason for this is to remove the salt water out of the bearing housing so it can't crystallize. If the shaft rotates irregularly, it can cause some rollers to develop a flat spot. This will have been caused by a temporarily blocking of the rollers by dirt parts. In most cases this will have been caused by dirt falling in from above on open tube systems. Use a gaiter to prevent this in the future. PYI Inc. can make you a Jefa Gaiter, please contact us for more details.

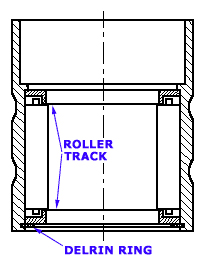

The removal of the rollers is quite simple: Drop the rudder out of the ship. Remove the thin delrin ring holding the roller track. Now the rollers and roller track will fall out. Mount the new rollers. To ease this job one can use a balloon to keep the rollers in place (NEVER use any grease). Mount the bottom roller track again and clip-in the newly supplied delrin ring. Watch the YouTube video below for instructions.

When you are experiencing a stiffer rudder and steering feel than normal, it could be caused by a corrosion or lime problem in the bearing. Please read this service tip for more info.

Lip Seals

If lip seals are used to seal your rudder system, please carefully inspect them for signs of cracks. If the seals show signs of cracks in the surfaces, immediately replace them with our new type PUR seal. These seals have no steel components inside anymore and will last much longer. It's advisable to spray a small film of teflon spray on the lip surface for better operation on the shaft. Manuals for replacing lip seals can be found here. It's advisable to inspect PUR seals once a year for defects.

Gaiter

Gaiters should be inspected every year for mechanical damage. Carefully inspect the gaiter for any signs of cracks, especially around the hose clamps. If you don't trust the sealing capabilities of the gaiter any more, replace it with a new one. Gaiters can be supplied in unglued state, so the rudder shaft doesn't have to be dropped. Wrap the new gaiter around the rudder stock, apply the specially supplied neoprene glue on the indicated area. Carefully press the surfaces together and let it dry for a while. Secure with the hose clamps again. For details about the appropriate dimensions, see the installation section.

Top Bearing

The top bearing doesn't usually require any maintenance. Only if your yacht is located on a sandy environment and the bearing is exposed (no deck cover present), you should rinse the bearing to wash away any sand and dust between the rollers and the housing. This should be done every year.

Vertical Locking

The vertical locking mechanism should be inspected yearly for any signs of movement relative to the shaft. Its advisable to loosen the set screws one after each other to be re-greased. This will make sure the vertical locking can be removed in the future for the possible removal of the rudder stock. For details about the proper mounting procedures, see the installation section.

If the vertical locking is achieved by a locking ring or tiller head on a delrin ring, you could experience a squeaking noise. This can be prevented by spraying a some teflon on the delrin ring.