FAQ

Here are common questions we receive about KiwiGrip. If you can't find an answer to your question here please feel free to contact us.

GENERAL

KiwiGrip is an anti-slip marine deck coating that is a revolutionary, safe, non-toxic, durable, non-skid deck treatment. KiwiGrip comes out of the can with a thick, yogurt-like, consistency — but spreads quickly and easily with the included roller. KiwiGrip offers a beautiful, consistent, grippy surface. By varying the application technique, the texture can be adjusted from "fine" to "aggressive."

Unlike other marine anti-skid deck coatings, KiwiGrip was developed by a New Zealand yachtsman for yachtsmen. It’s not just another industrial product stumbling upon a marine application.

KiwiGrip is...

- A very hard acrylic polymer providing a durable, homogeneous, elastic anti-skid surface

- Low-glare, IR reflective finish

- Homogeneous color – won’t wear through and expose filler materials

- Available in white, cream, light grey, light blue, and now black and neutral (ideal for tinting)

- Choose the perfect texture for your application with our special roller cover (included with order)

- Apply over wood, fiberglass, epoxy, concrete, or metal (metal surfaces must be properly primed)

- Rolls on nicely over other worn non-skid surfaces with only a scrub and scuff-up — no need to grind or sand smooth first

- Non-toxic, no volatile solvents

- No toxic solvents or cleansers needed to prepare surface

- Cleans up with soap and water

KiwiGrip is a homogenous material, so it doesn’t present the problems encountered with products filled with sand, walnut shells, beads, rubber fleck, or other fillers. Anti-skid coatings with fillers tend to wear through, and the fillers fall out — leaving an unsafe deck that’s hard to clean and even harder to re-coat. With KiwiGrip, re-coating is a breeze, and repairs are invisible.

KiwiGrip is applied by brush and our special texture roller, and is considerably easier, faster and less expensive to apply than spray or two-part anti-slip deck coatings.

Stock Answer: Each liter covers 2 square meters (about 20 square feet). Application is very thick – about 2 to 3 mm (a little less than 1/8 inch). A 4-liter kit will generally be sufficient for a 30 foot sailboat.

You can check to see if there is a KiwiGrip retailer, dealer or distributor near you on our Dealer Locator Map. Check back on our website from time to time as we periodically add new distributors.

Like any other coating, your success will depend as much on your application technique, surface preparation, temperature and humidity as it does on our product. Therefore we provide a warranty only in very limited conditions. We are confident you will be satisfied with KiwiGrip if you apply it according to our recommendations. We strongly advise you to select a small surface such as a hatch lid or floorboard for testing before committing to the whole project.

This depends on your usage. If you are a weekender, you can expect 10 years or more on your decks and a couple years less in your high-traffic cockpit. If you’re a deck-scrubbing fanatic or live aboard, you might see 5 years between re-coating your high-traffic areas. In terms of "use-days," you can expect about 1,000 days using your boat.

In heavy use or commercial environments, even though the surface may wear away more quickly, it is easy to renew by simply washing well and applying a refresh to the high traffic areas.

KiwiGrip will have about a 2-year shelf life from the time of purchase. Be sure to store KiwiGrip somewhere where it will not freeze.

If you have any leftover KiwiGrip, squeeze as much air out of the pouch as possible before sealing it back up again. This will help prolong the shelf life.

Getting a SuperYacht quality result depends on technique AND WEATHER CONDITIONS. KiwiGrip won’t cure properly in cold humid conditions. Here’s a rule of thumb: if the temperature (or 24 hour forecast) is under 50°F (10°C) and humidity exceeds 75%, wait for a warmer, drier day. Also DO NOT ALLOW DEW to settle on your fresh KiwiGrips before it is dry to the touch. If in doubt, run a small test patch (6" x 6") a day ahead. You should expect good adhesion without cracking in the finish!

To remove KiwiGrip it is normal to grind it away, make repairs and then re-coat to patch. The nice thing about KiwiGrip is that patching can look very good because of the rough texture, so repairs can be almost undetectable.

Unfortunately, KiwiGrip isn’t easy to remove — it will need to be physically ground away if there are large areas to remove (as would most coatings of this type).

Since it is a thermoplastic material, it will soften with heat. You can try heating it with a heat gun for paint stripping, and scraping with a putty knife.

Yes, Because KiwiGrip is a water based product, you can add the appropriate amount of water back to the product to match the viscosity of the new paint.

We have good success with 3M 4200, 5200, UV4000, and several other polyurethane sealants. We advise against using polysulfide sealants since they can cause crazing in the KiwiGrip.

KiwiGrip is a water-based product that will be destroyed if frozen. We try not to ship the product in the wintertime when temperatures are cold enough to freeze. KiwiGrip has a good network of distributors in place all over the world to help the end user mitigate this issue, as well as save time and money in shipping costs by finding the product locally. Our network is expanding quickly to ensure more and more stores, chandleries, distributors and contactors have it available. Please be sure to keep your spare cans of KiwiGrip from freezing so it can be used for repairs and recoats later down the road.

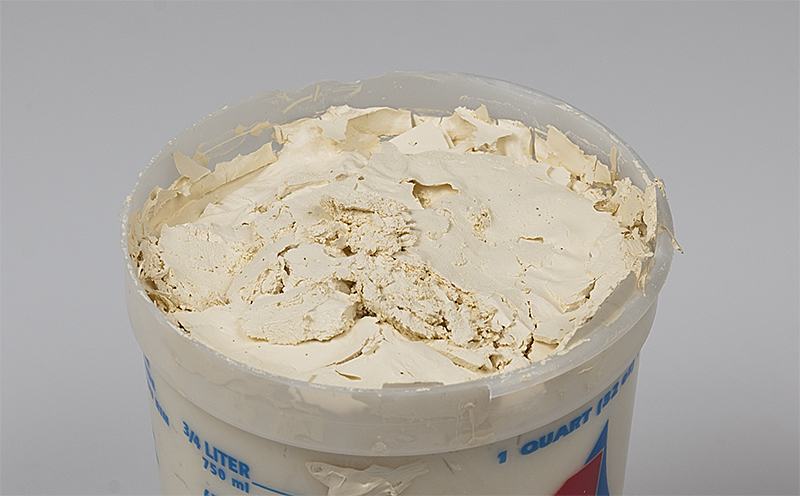

KiwiGrip after it has been subjected to freezing temperatures overnight.

- Shake in pouch, squeeze, spread and roll to desired texture.

- Purge air from pouch and reseal for easy, safe storage.

- No risk of product loss in transit due to dented cans.

- Less plastic per liter than previous can packaging with roller cover.

After full cure (a few days) scrub your new decks with fresh water to remove a soap-like component (surfactants) that migrates to the surface during KiwiGrip’s curing process.

SURFACE PREP

Masking is always advisable for the best result. Always remove the masking tape when KiwiGrip is still wet. Otherwise, you’ll need to use a razor blade to cut the KiwiGrip away from the tape edge. If you’re careful when re-coating, it is not necessary to mask since, with practice, you can carefully drive your loopy-goopy roller along the non-skid edge. When pulling your tape, you will find it provides a cleaner finish to pull slightly towards the painted section as opposed to away from it. This will allow any excess wet KiwiGrip to fall onto the painted surface as opposed to the unpainted deck that will require clean-up.

Take care to roll at a slow pace. If you speed up the process, the roller will create overspray of KiwiGrip onto surrounding surfaces.

No. Following a good sand-up and acetone wash we get a moderate bond to Starboard®. It is certainly fine for cosmetic surfaces, but not adequate for floors or other worn surfaces.

Yes. KiwiGrip does not act as a sealant. Therefore there are microscopic pores in the applied product that will allow water to reach the substrate. KiwiGrip will have no issues sticking to the metal surface, but the surface should be protected from water damage with an epoxy primer.

Please see our detailed instruction booklet here. KiwiGrip is not a sealant. All substrates must be sealed to protect against water intrusion (fiberglass, wood, aluminum). Gelcoats will need to be abraded with 60-100 grit sandpaper and then thoroughly cleaned with a degreasing boat soap. We do not recommend using dishwashing soaps or detergents, as they will commonly have grease in them. Do not treat the prepped surface with acetone or any other solvent based cleaners. The solvents left by the acetone take time to flash away and may cause crazing and adhesion problems for the KiwiGrip.

Yes. A de-waxing agent is required if the surface has been waxed within the last five years or if there is evidence of wax. An example of a de-waxer would be West Marine's Thinner & Dewaxer (Model #5437207). If there is concern about whether or not wax still exists on the surface, spray the surface with water from a spray bottle. If the water beads up on the surface, there is still wax present that needs to be removed.

Yes, KiwiGrip can be applied over LPU without any issue at all. An issue may arise when LPU is applied over KiwiGrip though. Some people will apply LPU paints over KiwiGrip to color match. This will likely cause crazing in the KiwiGrip because of the solvents in the LPU paint. The downsides to painting over the KiwiGrip is that:

- You may reduce the quality of the non-skid properties of the KiwiGrip.

- Over time, the LPU overcoat will wear away showing the original nonskid color through.

- The aforementioned crazing may occur in the KiwiGrip.

Yes. Concrete must be fully cured and sealed with any non-silicone sealer. Follow with a good soap and water scrub, allow to dry, and apply KiwiGrip. If you prefer not to seal the concrete: provided the concrete is clean and free of any surface contamination, release agents, cement dust, etc. and is not subject to water getting into the concrete from behind or hydrostatic pressure, KiwiGrip will work well by following these instructions:

- Thin a portion of the KiwiGrip with 25% water, and apply with a standard paint roller.

- Let that to dry for > 4hrs 20°C (68°F), and then follow with the KG application.

APPLICATION

KiwiGrip anti-skid deck system is the perfect do it yourself project.

- KiwiGrip rolls on quickly and easily

- One-coat application

- Cures in 24 hours

- Cleans up with soap and water

- Water-based acrylic polymer, non-toxic, no volatile solvents

- Work can be done on the hard or on the water

- Easy re-coat and repair: Just clean the old and roll on the new

- No masking required — although it is recommended

The non-skid properties of KiwiGrip come from the texture applied by our proprietary "loopy-goopy" roller. As the roller passes over the coating, the open cells of the foam roller leave peaks behind — not unlike the stipple that results when you roll paint on a wall or ceiling. By pressing firmly on the roller, you can get taller peaks. Light pressure on the roller will give you a less aggressive texture. A super aggressive texture can be attained by allowing the fresh KiwiGrip to get slightly tacky and then rolling over again. It’s VERY IMPORTANT to experiment on a small surface and determine which technique will provide you with the amount of anti-skid you require for your project before you tackle the whole deck.

For a very aggressive texture, allow the coating to partially dry, then re-roll to lift the settled peaks back up sharp. We call this back-rolling. You will have to experiment a bit to find the best delay for back-rolling in your conditions. We suggest you back roll every 5 minutes to find the delay when your KiwiGrip is thickening but not yet tacky.

Most customers are happy to slather the KiwiGrip around with a 4" brush averaging a coating thickness of about 2mm (between 1/16 and 1/8 inch). They even out the coating with the loopy-goopy texturing roller. We also suggest using a serrated 4" putty knife or notched trowel with 1/8 inch "saw-teeth" to spread the KiwiGrip on the decks. This yields a very consistent thickness ahead of the roller.

If you’re coating over a darker surface, two thin coats with brush and roller will yield a more consistent coating thickness than a single thick layer, since thin areas in the first coat will be corrected during the 2nd coat.

Yes. To prepare the old nonskid to accept KiwiGrip, scrub the surface thoroughly with a rotary green pad or wire brush, making sure that all the peaks and valleys are well dulled off. Then scrub with boat soap and water, allowing the surface to dry before masking and applying KiwiGrip. KiwiGrip will typically hide old non-skid that is less than 1.5 mm in height.

Apply only when surface, air and product temperature is 50° to 90°F (10° to 32°C). Normally it dries in one hour at 77°F (25°C). Allow at least 4 hours before re coating. High humidity may prolong drying time.

At 60° to 70°F, KiwiGrip will tack up in under an hour. You can walk on your new decks without shoes in 12 – 24 hours. Your decks will generally be ready for soft sole shoes on the 2nd day after application and hard sole shoes on the 3rd day. The coating will harden progressively over the first couple of weeks.

The above advice holds when the temperature (F) roughly matches the percent humidity. That is 40°F and 40ish % humidity or 90°F and 90ish % humidity. With low temperature and high humidity, drying will be very slow. With high temperature and low humidity, your working time with the product will be very short, and drying will be accelerated.

KiwiGripping is technique sensitive. Here are a few tips for achieving a super-yacht quality finish:

- Apply a consistent amount of KiwiGrip with your brush or trowel before rolling texture.

- One person should do all the slathering. One person should do all the rolling. This helps reduce variability due to differences in technique.

- Maintain wet working edges between sections by working small areas, so you can move to the adjoining section before the first begins to set up. Think of painting an interior room. You get best results by starting in a corner and rolling up and down, floor to ceiling. Then you move over 9 inches or so and roll floor to ceiling again, keeping your roller wet with paint. You proceed all the way around the room, always working with wet paint. Avoid rolling wet KiwiGrip up and over a previous section that’s already started to dry – this will cause a slight texture difference in the lap area.

A 4 inch roller provides better control than a larger roll, even so the project will advance quickly. It’s important that only 1 person does all the rolling to avoid slight differences in texture resulting from different rolling styles/techniques. A 2nd person is a big help to do the slathering and peeling up the masking tape as the roller moves along. Allow about 6 hours to do a complete 30 footer with a helper.

If you’re doing your KiwiGripping with the hardware still on your deck, you’ll want to buy a 2nd 4 inch roller that you can cut down into a 1 inch size and then a few 2 inch paddles (cutting the 2 inch roller lengthwise. These paddles are good for daubing the texture under handrails and cleat horns.

We offer a 9 inch roller for 2 specific cases:

- Very hot weather when you have to lay down a lot of KiwiGrip without much working time. The 9 inch roller is faster.

- Very flat surfaces (no deck camber) like large catamarans or Navy ship decks or docks, etc.

The problem with 9 inch rollers on yacht decks is that the deck has some camber to it. As you roll the larger roller fore and aft, the roller cannot compensate for the height differential, slight though it may be. You will exert less pressure on the ends of the roller than is applied in the middle resulting in an undesirable uneven texture.

Finally, your rollers will last a lifetime if you wash them well in fresh water after each use.

Do not roll quickly or vigorously as this will cause overspray splatters onto surrounding surfaces.

No. Following a good sand-up and acetone wash we get a moderate bond to Starboard®. It is certainly fine for cosmetic surfaces, but not adequate for floors or other worn surfaces.

Yes. KiwiGrip does not act as a sealant. Therefore there are microscopic pores in the applied product that will allow water to reach the substrate. KiwiGrip will have no issues sticking to the metal surface, but the surface should be protected from water damage with an epoxy primer.

We have good success with 3M 4200, 5200, UV4000, and several other polyurethane sealants. We advise against using polysulfide sealants since they can cause crazing in the KiwiGrip.

CLEANING

KiwiGrip is impervious to common caustics — such as cola, soda-pop, peanut butter, jelly, alcoholic beverages, and detergents — although it can be damaged by some solvents.

Diesel, oil, acetone, and gasoline spills should not be allowed to pool. There are harsh solvents in fuels, acetone, and some oils. Try your best to avoid making contact with these products on your KiwiGrip as it may result in permanent damage requiring KiwiGrip reapplication.

Quickly mop up spills, and promptly scrub with a detergent boat soap using a soft bristle brush and water.

KiwiGrip cleans up nicely with a good biodegradable boat soap, water, and a soft bristle brush that can penetrate the peaks and valleys. KiwiGrip can be high pressure washed if required, but it is often best to use a boat cleaning detergent first, then remove with high pressure water. You can use bleach if you wish, in a very mild form only.

Yes the acrylic formula is inherently mold and mildew resistant. You’ll find however, like any other anti-skid, if you don’t wash it regularly dirt will accumulate in the valleys providing fertile ground for mold and fungus growth. Stain resistance and non-skid surfaces are a conundrum. It is very difficult to have a very easy to clean, stain resistant surface that is also non-skid. KiwiGrip, however does not seem to absorb many stains and spots are easily scrubbed and washed away. You may occasionally notice staining where dead fallen leaves have been allowed to sit on the Kiwigrip for a long period of time. A cleaner high in oxalic acid or a wood bleach will help lighten or eliminate these stains.

RECOATING

Yes. To prepare the old nonskid to accept KiwiGrip, scrub the surface thoroughly with a rotary green pad or wire brush, making sure that all the peaks and valleys are well dulled off. Then scrub with boat soap and water, allowing the surface to dry before masking and applying KiwiGrip. KiwiGrip will typically hide old non-skid that is less than 1.5 mm in height.

Yes! This is a wonderful feature of KiwiGrip. You can re-coat after a good soap and water scrub. You can change color or texture during a re-coat, too.

KIWIGRIP COLORS

Standard colors are white, light grey, light blue and cream. Our standard colors have been selected for being low glare and as cool as possible underfoot in direct sunlight. The closest RAL codes for our standard colors are below. Please be advised that they are not exact matches, but the closest representations that we can find using the RAL standard of codes.

- White – RAL 9003

- Grey – RAL 7047

- Cream – RAL 1015

- Black – RAL 9004

- Blue – No RAL match

Yes, indeed! We use the same water-based tints that most paint retailers use. Technically, there is no limit to the color as long as it is a light color, since we start from a white base. Dark colors are not possible since the tint is quite runny and too much tint will destroy the non-skid properties.

Keep in mind that the standard colors we offer have been selected for being as cool as possible underfoot in direct sunlight. To achieve a custom color, you can buy our white KiwiGrip, take it to your local paint store and have them tint and mix it for you. Do not exceed 3% tint by volume. Please see our downloads section for detailed tinting instructions, or click here.

We have a swatch card available with our standard colors in an assortment of four different textures for a nominal fee of $3 in our webstore. We also encourage you to order a single liter of KiwiGrip and give it a try. Within 30 minutes on your own deck or on a sealed piece of plywood, you’ll be able to experiment with thickness, roller pressure, and back-rolling to achieve assorted textures. Don’t worry, if you don’t like the result the next day, KiwiGrip can be removed before a full cure.